Welcome to Our Company -

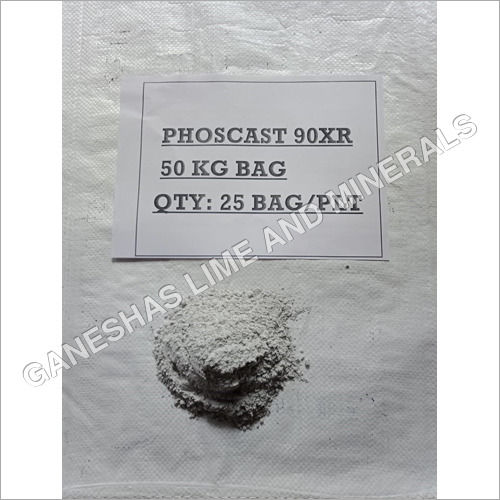

Phoscast 90XR

102.0 INR/Kilograms

Product Details:

- Application Industrial

- Product Type Mineral Refractories

- Types of Refractories Basic Refractory

- Shape Powder

- Click to view more

X

Phoscast 90XR Price And Quantity

- 102.0 INR/Kilograms

- 1 Kilograms

Phoscast 90XR Product Specifications

- Powder

- Basic Refractory

- Industrial

- Mineral Refractories

Phoscast 90XR Trade Information

- MUNDRA

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- 50000 Kilograms Per Month

- 30 Days

- No

- Free samples available with shipping and taxes paid by the buyer

- 25/50 KG BAGS

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO 9001:2015

Product Description

| Product Specifications | ||||

| Techinical | 1750c | Pre Liquid For Ramming (%) | 10.7-11.5 | |

| Feature | Resist chemical corrosion &Strong resistance to slag erosion and penetration | Thickness | ||

| Grain Size | 0 to 4 mm | Color | White | |

| Dry Density(G/cc) | 2.75 -2.85 | Packaging Details | 25/50 Kg Bag | |

| Type | Powder | Type | Phosphate Bonded | |

| Material | Refractory Castable | |||

GANESHAS has taken a number of approaches to identify the key factors affecting erosion rates with an objective to enhance the life of inbed tubes as well as implementing the corrective action to reduce the erosion rates.Phosphate coatings are often used to protect steel parts against rusting and other types of corrosion.Erosion of inbed coils in fluid bed combustor is an unavoidable phenomenon however the rate of metal wastage and thus the life of tubes depends on various factors like ash & fuel properties, design of Combustor/feeding system, flue gas velocities operating conditions, etc. It has been also observed that maximum erosion-prone inbed coils are those which come above fuel feed nozzles and an area of approximately 1 to 1.5 mts around fuel feed systems are badly affected

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese